This system uses an innovative, proprietary technique to vaporize liquid samples for injection in an existing GC system.

The Vaporizer is useful for methods requiring a larger sample injection size than typically provided by liquid sampling valves (LSVs).

Liquid sample valves can have problems with density changes and premature vaporization due to the valve getting hot. With our vaporizer, all liquid samples are vaporized and run at a constant pressure, eliminating sample density changes that cause errors in liquid phase samples. This ensures sharp, easy-to-read peaks for all samples.

The system provides repeatable sampling of volatile liquids that may flash vaporize in an LSV.

For GC systems with multiple channels, a vaporizer can reduce the required hardware and associated expense.

Not only does Wasson-ECE manufacture turn-key laboratory and process solutions, but we are also at the forefront of sample introduction solutions in the hydrocarbon processing industry. We manufacture process sample panels, custom sample introduction systems, and small devices to streamline the sample handling process for our customers.

Wasson-ECE’s LPG Vaporizer is more convenient than a typical liquid sample valve with more accurate results. Liquid sample valves can have problems with density changes and premature vaporization due to the valve getting hot. With our vaporizer, all liquid samples are vaporized and run at a constant pressure, eliminating sample density changes that cause errors in liquid phase samples. This ensures sharp, easy-to-read peaks for all samples.

High Sample Throughput

A small internal volume on our vaporizer along with purging minimizes the chance for cross contamination, and the internal valve allows the pressure to be bled off quickly when switching samples, thus allowing for fast sample switching.

Consistent and Accurate Samples

Wasson-ECE's unique, proprietary vaporization technique produces an even and accurate gas sample. Other vaporizers use tubing with a large volume, causing samples to fractionate when vaporized. This can lead to incomplete sample analysis. The LPG Vaporizer controls the injection volume so that all elements in the liquid sample are vaporized and sent to the GC simultaneously, producing a complete and accurate analysis of the sample.

Wasson-ECE’s Vaporizer offers flexibility for both gases and liquids using a single valve, includes specially passivated sample tubing for the analysis of trace reactive analytes, enables the use of gas calibration blends, allows for high sample throughput, and gives sharper peaks and accurate results.

The system is designed with an ultra-low internal volume of 35µL and includes a user selectable heater. A separate heater maintains this temperature through a heated transfer line to maintain temperature and prevent line condensation.

The Vaporizer is useful for methods requiring a larger sample injection size than typically provided by liquid sampling valves (LSVs). The system provides repeatable sampling of volatile liquids that may flash vaporize in an LSV and, for GC systems with multiple channels, can reduce the required hardware and associated expense.

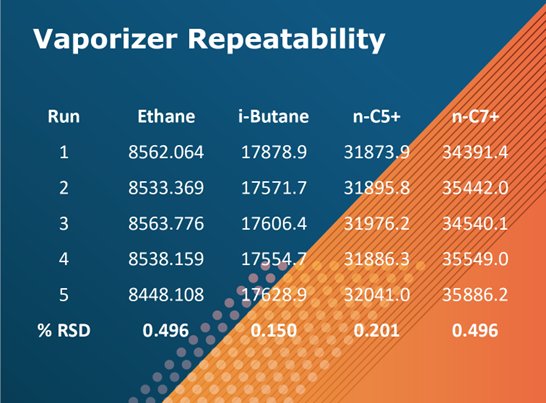

Wasson’s Vaporizer gives excellent repeatability

Stand Alone Model 1107 – can be used with a variety of GC models.

On-Board Vaporizer – integrated into Wasson/Agilent GCs.

- Vaporizes liquified petroleum gas (LPG) such as C3, C4 hydrocarbon mixtures

- User selectable heater <150 C

- Heated sample transfer line to GC (30”, 1/16”)

- Air actuated selection valve for sample porting to the GC

- Ultra-low internal volume of 35uL

- Specially passivated sample tubing for the analysis of trace reactive analytes

- Maximum vaporizer temperature: 150°C

- Bypass for gas sample injections

- Maximum input pressure:

- Liquid sample: 1000 psig

- Gas sample: 300 psig

- Actuation gas: 65 psig

- Dimensions: 10”W x 8”H x 20”D

- Weight: Approximately 25 lbs

- Minimum required electrical supply: 115/220V

Lab Devices Brochure

D2712

Wasson-ECE Instrumentation

101 Rome Ct., Fort Collins, Colorado USA 80524

Phone: +1 (970) 221-9179

Fax: +1 (970) 221-9364

© 2025. All Rights Reserved.

When you can't afford to be wrong. TM